Hot Runner Components

Sprue Bushings

The Integrally Heated Sprue Bushing is uniquely designed for high performance and reliability for Manifold and Direct Feed Applications, even with the most demanding molding cycles and plastic resins. The advanced heat transfer capability is attributed to its integrally heated design, resulting in a more uniform heat profile. A replaceable thermocouple is strategically located close to the melt flow channel for optimization of processing conditions with all thermoplastics.

Precision Series Direct Gate Bushing

The New Precision Hot Runner Bushings & Nozzles are designed to run mid-size and large molded parts. Advanced heat transfer technology provides optimum performance while a unique sleeve heater design allows for easy and quick replacement. The special tip design allows the Precision to process commodity, engineering and filled resins while drastically reducing tip wear at the gate. The Precision has eleven different gating options to meet a wide range of Direct Feed or Manifold applications.

Machine Nozzles

The integrally heated machine nozzles unique design concept eliminates the voids and air gaps which limit the performance of conventionally heated nozzle systems. The improved heat transfer characteristics of the Sensitip? Machine Nozzle provide performance and reliability far superior to any existing nozzle designs.

A replaceable "Type J" thermocouple senses temperature adjacent to the melt channel. This accurate sensing system works in conjunction with a very uniform temperature profile to ensure superior processing of even the most critical of engineering materials.

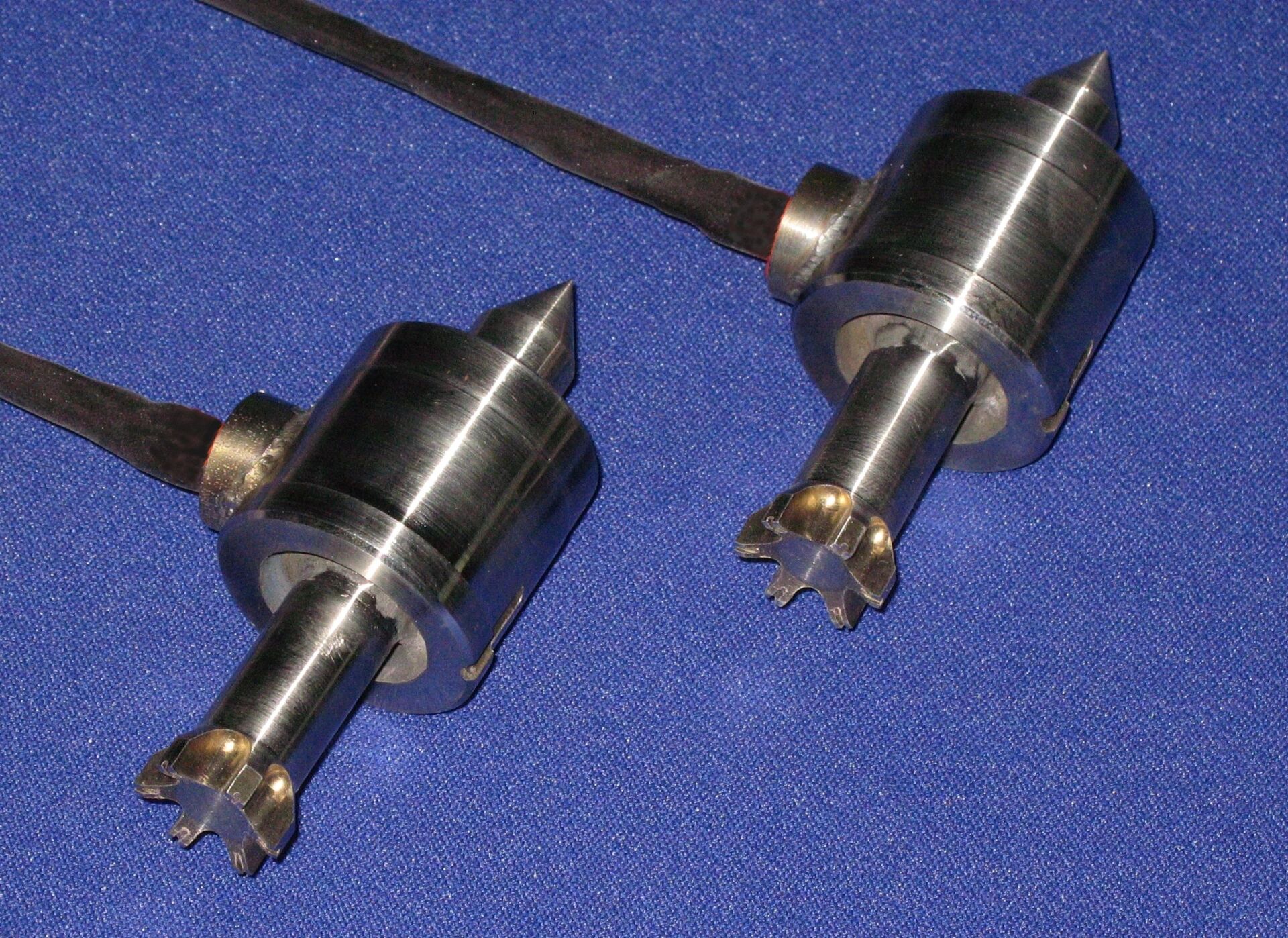

M.I. Thermocouples

The "TRUTEMP" drawn cable sensors feature durability, fast response and high temperature capabilities. Drawn cable sensor constructions combine precision fabrication techniques with premium quality mineral insulated cable and feature rugged construction in a particularly compact size.

The standard construction consists of an appropriate pair of elements embedded in compacted ceramic and encased in an appropriate tubular sheath. These elements are welded to form a thermocouple junction or attached to RTD sensor elements. A wide variety of standard and custom fittings can be added to the sensor to simplify installation and application. The lead end of the cable is typically equipped with connectors or leads to accommodate connection to control system wiring.

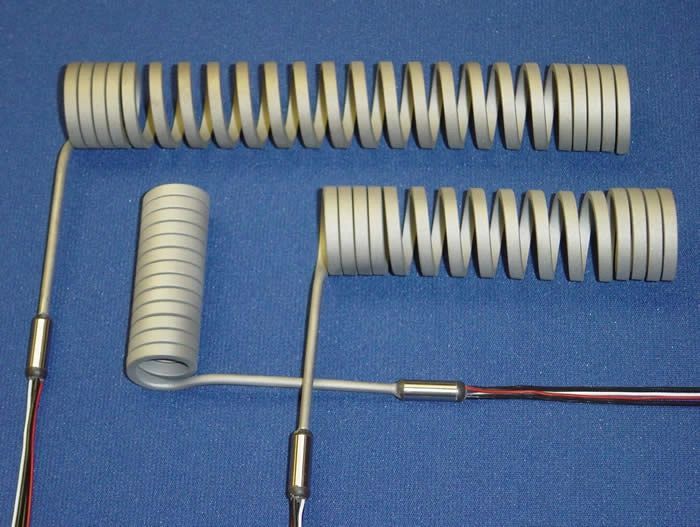

Electric Coil Heaters

"MAXPAK" high performance cable heaters are offered in a variety of round, square and rectangular cross sectional constructions. Standard configurations include precision coiled or formed configurations as well as straight styles intended for customer forming. Straight “MAXPAK” cable heaters are fully annealed and are designed to satisfy customer in-house forming and coiling requirements as well as providing a range of stock elements for expedited delivery. Formed “MAXPAK” cable heaters are factory formed to customer specifications. Precision coiled “MAXPAK” cable configurations are available in both stock configurations and custom coiled to customer specifications.

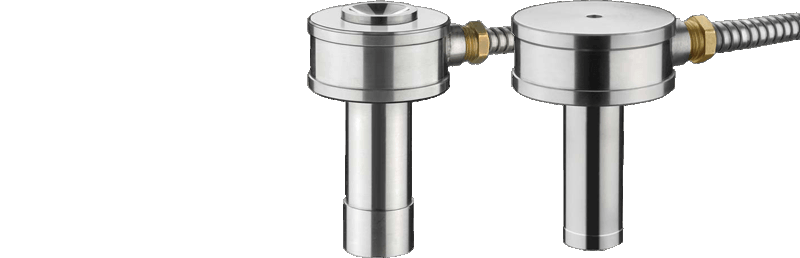

Machine Shut Off Nozzles

Osco's MSO - Machine Shut Off nozzle : Machine shut off nozzle is designed to improve profitability by providing positive shut off allowing for faster cycle times and eliminating drooling caused by back pressure. Performance and design flexibility with several tip styles, available in hydraulic or pneumatic operation.

Machine shut off nozzle is designed to improve profitability by providing positive shut off allowing for faster cycle times and eliminating drooling caused by back pressure. Performance and design flexibility with several tip styles, available in hydraulic or pneumatic operation.

Features:

- Tip design to suit

- Hydraulic or Pneumatic drive

- Length to suit

Let's Make It Happen!

Set Up Your Complimentary Consultation Today

Frequently Asked Questions

-

What is Red Heat Technology Sales?

Redheat Technology Sales is a first class professional manufacturers’ representative company founded on the principles of providing OEMs, distributors, and users exceptional customer service and innovative products. Paul F. Hurley, owner of Redheat Technology Sales, enjoys over 34 years experience in the temperature management, heating elements, plastic injection molding.

Redheat Technology Sales is an independent sales company representing top quality equipment manufacturers and molders. We represent the equipment manufacturers Tutco Electric Heaters, Tutco Flexible Heaters, Duratherm Heaters, and Thermocouples. For molders, mold makers, and die builders, we represent OSCO Runnerless Systems, DMS Mold and Die Components, ITC Temperature Controllers, Zeiger Industries, and Tremblay Tool Steels.

Our objectives are to provide the best service and products we can. We aim to sell the highest quality standard and custom made engineered electrical and electro-mechanical components to OEMs with superior customer service. We also aggressively represent a limited number of principals whose products are synergetic with the goal of gaining market share. We strive to effectively support and grow a distributor network to sell to users and to sell hot runner products to the plastic injection molders and mold makers.

Our strategy to achieve these objectives includes providing resourceful and cutting edge technical solutions for customers, looking for value added opportunities, and seeking out early winning design engineering opportunities.

-

What experience does Paul Hurley have?

Paul Hurley has a wealth of experience in technology sales. He spent twenty years in Elmhurst, Illinois in charge of direct sales for the northeastern region of the United States. He sold electric heating elements, hot runner components, hot runner systems, and temperature controllers to OEMs and users. He also developed and managed the distribution network, gained over a million dollar market share, and continuously exceeded sales goals and achieved the top salesman award. He also acted as the regional manager for the northeastern region of the United States for two years, establishing and overseeing independent sales representatives and distributors.

Navigation

Redheat Technology Sales LLC

All Rights Reserved | Redheat Technology Sales LLC