Hot Halfs

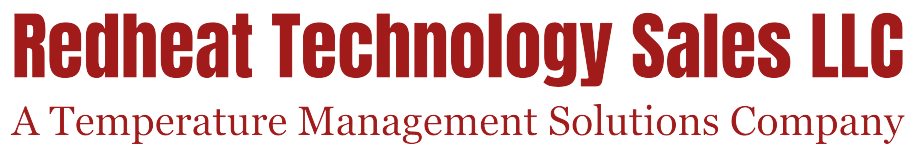

OSCO's Hot-Half System is designed to facilitate the Hot Runner interface. Furnished complete with the Top Clamp Plate, Nozzle Retainer Plate, Support Rails, Locating Ring and the OSCO Runnerless System assembled, installed and electrically tested. Features/Benefits:

- Simply fasten the Hot-Half to the mold base and you are ready to run.

- Eliminates the time, effort and challenges associated with the Hot Runner installation.

- Can reduce mold delivery time by allowing you to concentrate on cores and cavities.

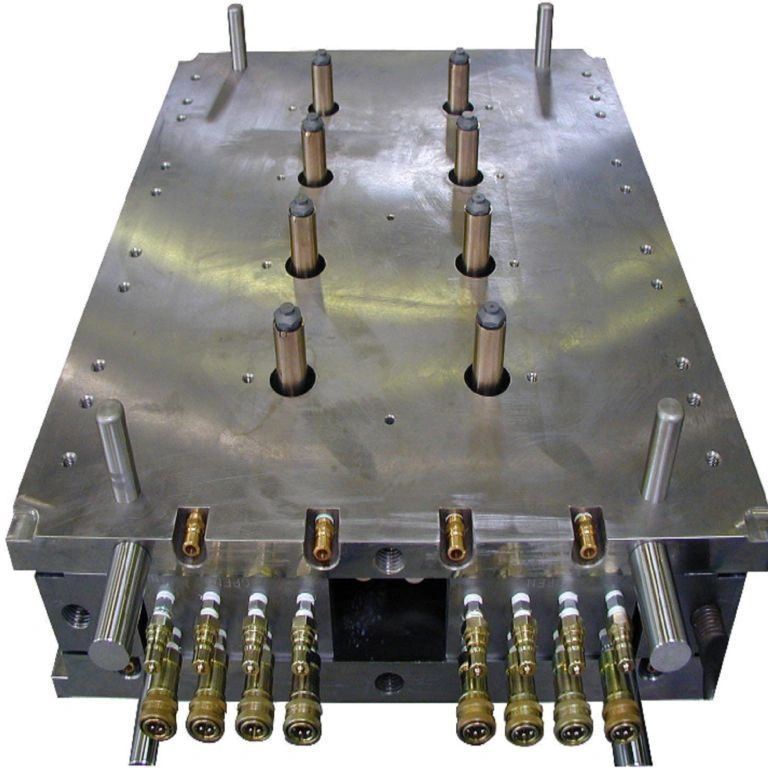

Prewired Systems

The Pre-Wired option will simplify the installation of the manifold system into your mold. Furnished with OSCO standard “PIC” and “MTC” type mold connectors, electrical schematic, wiring arm secured to the manifold, and a wiring schematic plaque fastened to the terminal box for easy in-press zone identification. * Save time during installation and disassembly. * Neat and clean wiring installation will help you avoid down time. * Clearly marked and labeled wiring zones assure you that the electrical system is both reliable and accurate.

MGN - Multi-Gate Nozzles

Designed for single or manifold applications, OSCO'S MGN Systems are simple, straightforward units providing up to 12 gate probes per nozzle.

Features/Benefits:

- Variable probe lengths, locations & number of probes.

- Individual temperature control at each gate.

- Minimal residence time.

- Balanced flow.

- Process engineering grade resins.

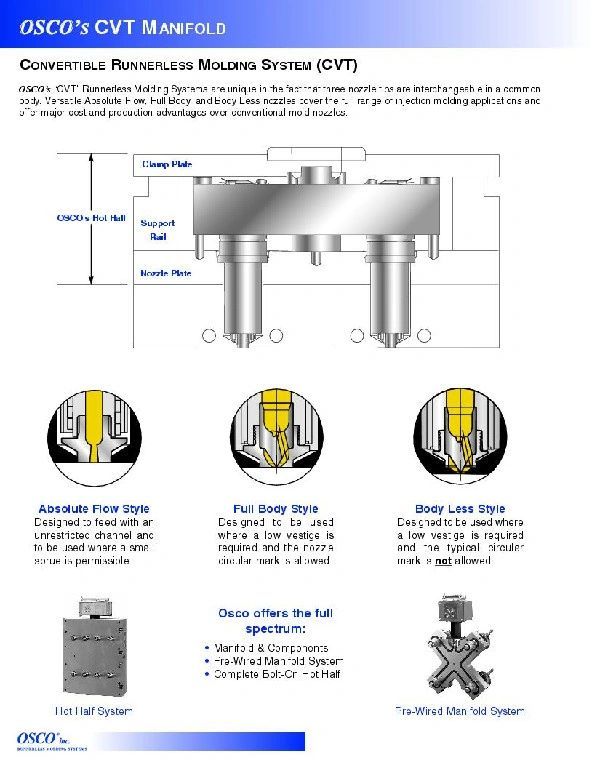

CVT - Convertible Direct Gate Nozzles

Originally patented by OSCO, the Convertible Series Nozzle System was the first to offer the flexibility of interchangeable nozzle tips. Features/Benefits:

- Flow channels from 1/4"

- Wide selection of nozzles, tips, and heaters in stock

- Custom lengths and diameters to fit the application

- "SF" heater design for the best combination of performance and flexibility

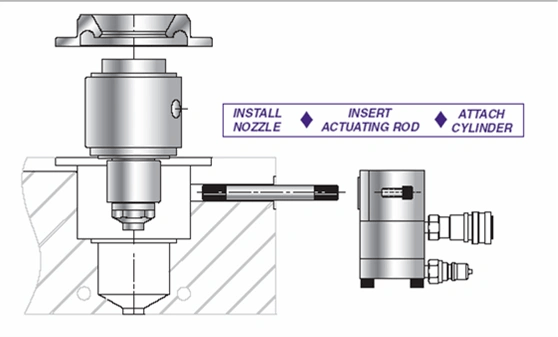

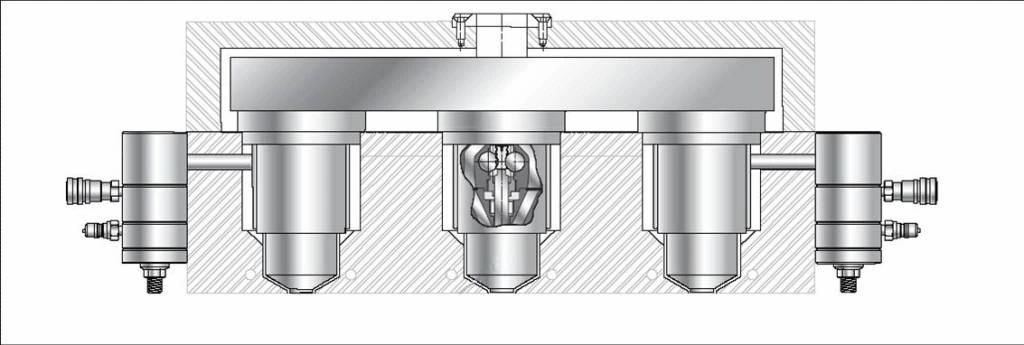

SCV - Self Contained Valve Gate

Engineered for use under a manifold or as a stand alone Single Valve Gate, the SCV Nozzle Systems are by far the most technologically advanced Valve Gate Systems on the market today.

Features/Benefits:

- Gate diameters up to .375.

- Adjust and set Valve Pin from the Hydraulic Cylinder Assembly (HCA).

- View Valve Pin movement from indicator on the HCA.

- HCA mounted outside the mold substantially reduces cost associated with machining, installation, service, and operation.

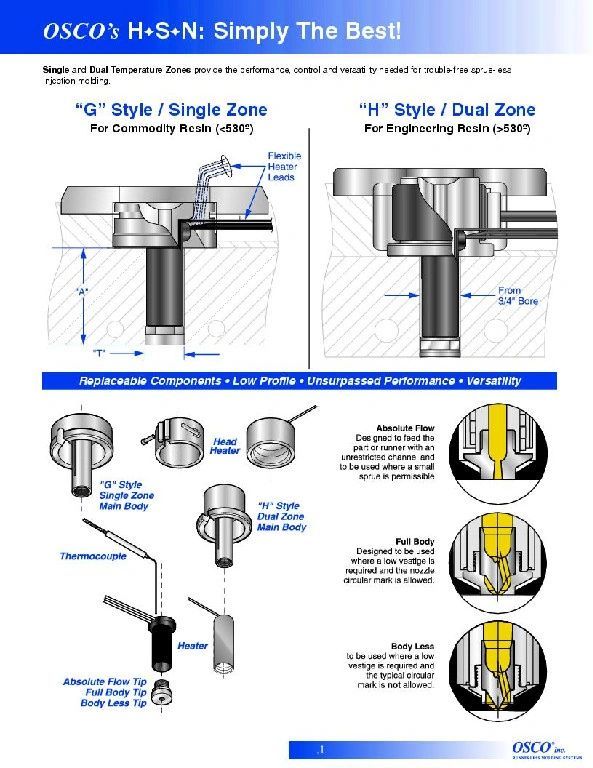

HSN - Hot Sprue Nozzles

Designed to eliminate the sprue in single nozzle applications. To meet the industries needs, we offer the HSN with one or two zones of temperature control. The single zone, or "G" Series nozzle is a more cost efficient selection when processing commodity grade resins. The "H" Series is the high performance dual zone nozzle. It is an excellent choice for processing high heat engineering grade resins as well as heat sensitive resins.

Features/Benefits:

- Eliminate sprues and secondary operations.

- Directly replaces cold sprue bushings (in most applications).

- Wide selection of nozzles, tips, and heaters in stock.

- Interchangeable tips for design flexibility.

Let's Make It Happen!

Set Up Your Complimentary Consultation Today

Frequently Asked Questions

-

What is Red Heat Technology Sales?

Redheat Technology Sales is a first class professional manufacturers’ representative company founded on the principles of providing OEMs, distributors, and users exceptional customer service and innovative products. Paul F. Hurley, owner of Redheat Technology Sales, enjoys over 34 years experience in the temperature management, heating elements, plastic injection molding.

Redheat Technology Sales is an independent sales company representing top quality equipment manufacturers and molders. We represent the equipment manufacturers Tutco Electric Heaters, Tutco Flexible Heaters, Duratherm Heaters, and Thermocouples. For molders, mold makers, and die builders, we represent OSCO Runnerless Systems, DMS Mold and Die Components, ITC Temperature Controllers, Zeiger Industries, and Tremblay Tool Steels.

Our objectives are to provide the best service and products we can. We aim to sell the highest quality standard and custom made engineered electrical and electro-mechanical components to OEMs with superior customer service. We also aggressively represent a limited number of principals whose products are synergetic with the goal of gaining market share. We strive to effectively support and grow a distributor network to sell to users and to sell hot runner products to the plastic injection molders and mold makers.

Our strategy to achieve these objectives includes providing resourceful and cutting edge technical solutions for customers, looking for value added opportunities, and seeking out early winning design engineering opportunities.

-

What experience does Paul Hurley have?

Paul Hurley has a wealth of experience in technology sales. He spent twenty years in Elmhurst, Illinois in charge of direct sales for the northeastern region of the United States. He sold electric heating elements, hot runner components, hot runner systems, and temperature controllers to OEMs and users. He also developed and managed the distribution network, gained over a million dollar market share, and continuously exceeded sales goals and achieved the top salesman award. He also acted as the regional manager for the northeastern region of the United States for two years, establishing and overseeing independent sales representatives and distributors.

Navigation

Redheat Technology Sales LLC

All Rights Reserved | Redheat Technology Sales LLC